Hardwood vs. Engineered Wood Floors: Which Is Easier to Maintain?

You want the warmth of wood—but not the chore chart. If you’re comparing solid hardwood to engineered wood, you’re really weighing how the floor is built and how it’s finished against the kind of maintenance you’re willing to do.

Quick verdict: Day-to-day, engineered wood with a tough, factory-applied (UV-cured) finish is usually the lowest-effort option. Over the long haul, solid hardwood is often easier to renew because it can be sanded and refinished more times. Your climate, the finish, and the wear layer thickness on engineered planks are the big swing factors.

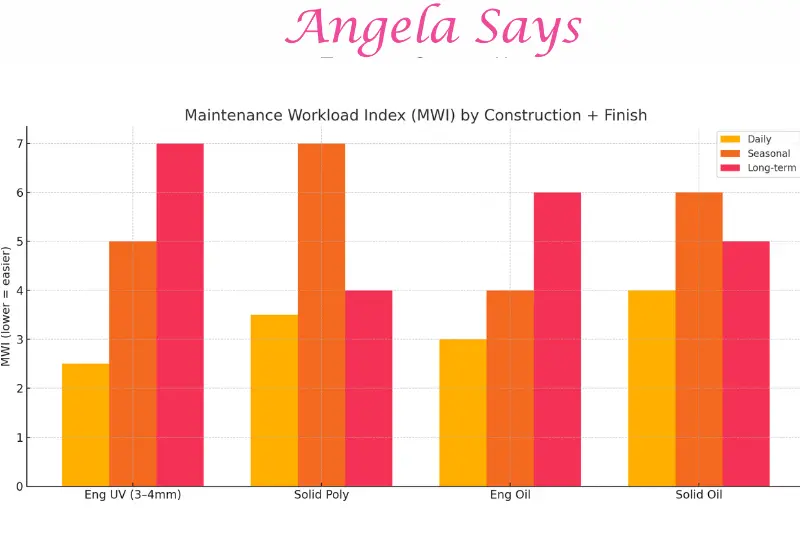

The 30‑Second Summary: Maintenance Workload Index (MWI)

To make this practical, here’s a simple Maintenance Workload Index (MWI). Lower scores mean less effort. We score three time horizons: daily, seasonal, and long-term.

| Construction + Finish | Daily MWI | Seasonal MWI | Long‑Term MWI |

| Engineered, factory UV (3–4 mm wear layer) | 2–3 | 5 | 7 |

| Solid hardwood, site-finished polyurethane | 3–4 | 7 | 4 |

| Engineered, hardwax‑oil | 3 | 4 | 6 |

| Solid hardwood, hardwax‑oil | 4 | 6 | 5 |

How to read this:

- Engineered wins for everyday ease and humidity tolerance.

- Solid hardwood wins for deep, long-term renewability.

- Oil finishes are great for spot repairs, but they need planned upkeep.

What “Maintenance” Really Means for Wood Floors

When people say “low maintenance,” they sometimes mean “I don’t want to babysit my floor,” and at other times, “I want to renew it easily in 8–10 years.” Maintenance spans three buckets:

- Everyday care: Dry dusting (microfiber) to remove grit; occasional damp mopping with a wood-safe cleaner; felt pads on furniture; mats at entries.

- Preventive management: Maintaining indoor relative humidity at ~30–50%, promptly addressing spills, and using breathable rugs.

- Deep maintenance:

- Screen & recoat (aka buff & coat): light abrasion + fresh topcoat.

- Full refinish: sand to bare wood, then stain/topcoat.

- Local repairs: spot oiling, color fill, or even a single‑board swap.

“Easier to maintain” depends on which bucket you care about most.

Anatomy That Affects Upkeep: Solid vs. Engineered

- Solid hardwood is a single species top to bottom. It moves more with seasonal humidity (gaps in winter, potential cupping in humid months), but can be sanded and refinished multiple times. If you like the idea of a “forever floor,” this is part of its appeal.

- Engineered wood is a real‑wood wear layer bonded to a multi-ply core (or HDF). The core resists movement, so floors stay flatter across seasons, and manufacturers often prefinish planks with super‑durable UV-cured coatings. Refinishing depends on wear layer thickness (e.g., ~3–4 mm can often handle 1–2 sandings; thin veneers usually can’t).

- Finish matters as much as construction:

- Factory UV, aluminum oxide: a very hard surface; superb for day-to-day durability; recoats require planning but are doable.

- Site‑finished polyurethane: a seamless film across the whole room; easy to recoat or fully refinish later.

- Hardwax oil: beautiful, matte, and spot-repairable; requires periodic maintenance oil.

Bottom line: Engineered and factory UV tend to be the easiest week-to-week; solid and site finish are simpler to renew deeply.

Day-to-Day Cleaning: Which Is Simpler?

- Grit is the enemy. Microfiber dusting a few times a week in high‑traffic zones is the single biggest scratch reducer.

- Damp mopping, not wet mopping. Use a wood‑approved cleaner; avoid steam, vinegar, or standing water.

- Edges matter. Prefinished planks usually have micro‑bevels, which can catch dust; a site‑finished floor is flatter across boards and slightly faster to wipe clean.

- Sheen choice helps. Satin/matte hides micro‑scratches better than gloss, especially in sunlight.

Verdict: Engineered with a tough factory finish usually takes the least daily effort. The coating is harder, and the floor moves less with seasons, so joints stay tighter.

Spills, Stains & Water Events

Spills are a race against time for any wood floor. Wipe promptly and you’re fine; let moisture sit and you risk edge curl, stains, or finish damage.

- Engineered’s stability helps with small moisture swings; fewer seasonal gaps means less water sneaking into seams. Still, it’s not waterproof—clean up at once.

- Solid hardwood can show cupping more readily if repeated moisture hits the same area.

- Finish type guides the fix:

- Poly/UV finishes resist stains well; if damaged, they’re harder to “feather” invisibly in a tiny spot.

- Hardwax oil absorbs into the wood; spot re‑oiling can blend minor water marks or abrasion without treating the whole room.

Pro tip: Put absorbent mats where liquid lives—sinks, pet bowls, entryways—and use breathable rug pads so moisture can escape.

Scratches, Dents & Wear Patterns

- Finish hardness vs. wood hardness: The species’ Janka rating matters for denting, but finish fights micro‑scratches. Aluminum‑oxide UV finishes are extremely tough; site polys are repairable; oils are the most forgiving for small areas.

- Camouflage is strategy. Matte sheen, wire‑brushed textures, and character grades hide wear far better than glassy smooth planks. Lighter, natural tones disguise dust and pet hair.

- Repairability spectrum:

- Micro‑abrasions: clean, lightly abrade, and recoat (poly) or spot‑oil.

- Deep scratches: color‑fill + topcoat; if the scratch crosses grain badly, swap a board (especially feasible with click‑lock engineered).

- Large, dull areas: screen & recoat the whole room for a uniform look.

- Heavily worn/stained: full refinish (solid, or engineered with adequate wear layer).

Verdict: Engineered often makes single‑board swaps easier; solid makes whole‑room renewals easier.

Humidity, Seasons & Climate Control

Wood wants a stable home environment. Indoors, ~30–50% relative humidity (RH) keeps planks content.

- Engineered is less sensitive to swings, so you’ll see fewer seasonal gaps and less cupping risk. That’s why many engineered products are approved for basements or radiant heat—still check the specific product rating and warranty.

- Solid hardwood likes tighter RH control. Expect gapping in dry winters and potential cupping in damp summers if you don’t manage humidity.

- Simple tools: A $15 hygrometer, felt pads, and entry mats prevent most headaches. In dry climates, consider a whole‑home humidifier; in humid climates, dehumidification or robust AC matters.

If you prefer a floor that stays visually consistent through the seasons with less oversight, engineered has the edge.

Deep Maintenance: Recoat vs. Refinish vs. Replace

Understanding the “big” maintenance options helps you plan—not panic.

Screen & Recoat (Buff & Coat)

- What it is: Lightly abrade the existing finish and lay down a fresh topcoat.

- When to do it: When cleaning no longer restores sheen and micro‑scratches accumulate, but the stain color is fine and the finish film is intact.

- Why it’s great: Fast, far less dust, and much cheaper than a full sand. It extends the life of both solid and engineered floors.

Full Refinish (Sand to Bare Wood)

- What it is: Sand off old finish (and minor damage), optionally change stain color, then re‑coat.

- Who can do it: Solid hardwood indefinitely; engineered only if the wear layer is thick enough (often ~3–4 mm can handle 1–2 sandings, while thin veneers cannot).

- Why it matters: It’s a “reset button”—you can remove most dents/scratches and even restain for a new look.

Board Replacement

- What it is: Remove and replace a damaged plank.

- Where it shines: Click‑lock engineered; surgical swaps are practical. Nail‑ or glue‑down planks can be replaced but require more labor.

Typical intervals: With average traffic, factory UV floors may not need attention for many years; oils want scheduled care (light maintenance oil) but reward you with easy spot fixes. Watching the surface—not the calendar—is the smarter trigger.

Real‑Life Scenarios: What’s Easiest in Your Home?

Humid/coastal climate or big seasonal swings?

Choose engineered with a factory UV finish. Its stability shrugs off humidity changes, so you’ll see fewer seasonal gaps. Keep RH roughly in range and you’ll do less fussing overall.

Cold/dry winters with forced air?

Either type works if you manage RH. Engineered is more forgiving if you forget to run the humidifier mid‑January.

Basements or radiant heat?

Go engineered that’s explicitly rated for below grade or radiant systems. Solid hardwood can work over radiant, but only specific species/widths and careful install—maintenance headaches often trace back to a mismatch here.

Pets, kids, sand, and salt?

You want matte, low‑sheen and either a wire‑brushed texture or a character grade that hides reality. A tough factory UV finish handles micro‑abrasion well; hardwax oil is excellent if you’d like to spot repair nail trails or pet‑dish zones quickly.

Rental or short‑term accommodations?

Engineered with a tough factory finish wins for durability and for board‑swap simplicity after a hard tenant turnover. Avoid high‑maintenance oil systems unless your cleaning crew is trained and stocked.

Design‑forward “forever home”?

Solid hardwood offers unmatched future flexibility: you can restain as tastes change and refinish multiple times. If you want a seamless, flush surface, consider site finishing after install.

Installation & Warranty Factors That Affect Maintenance

- Install method:

- Floating floors (often engineered) simplify future access and single‑board swaps.

- Glue‑down can feel quieter and sturdier underfoot but complicates replacement.

- Nail/staple‑down is classic for solid hardwood; easy to refinish later.

- Underlayment & moisture: The right underlayment improves sound and can add vapor protection over concrete slabs—key for maintenance longevity.

- Warranty fine print: Manufacturers specify approved cleaners, RH ranges, and rug pad types. Stick to them so you don’t void coverage.

- Keep extras: Save lot numbers and a few spare planks in case you need a perfect match for a board swap later.

Cost of Ownership: Time & Money (Worked Examples)

Costs vary by region and product, so treat these as directional apples‑to‑apples comparisons for a 600 sq ft space.

Assumptions

- Cleaning supplies: $60/year (pads + wood‑safe cleaner).

- Screen & recoat: $1.75/sq ft → $1,050 for 600 sq ft.

- Full refinish: $4.00/sq ft → $2,400 for 600 sq ft.

- We’ll ignore “time value of cleaning” since both floor types need similar weekly attention.

10‑Year Horizon

- Engineered (factory UV):

- Supplies: $60 × 10 = $600

- One recoat at year 8: $1,050

- Total 10‑year cost: $1,650 (≈ $165/year)

- Solid hardwood (site poly):

- Supplies: $60 × 10 = $600

- One full refinish at year 10: $2,400

- Total 10‑year cost: $3,000 (≈ $300/year)

Result: Engineered is typically cheaper in the first decade.

20‑Year Horizon (Two scenarios)

- Scenario A: Engineered with a thick wear layer (recoats, not replacement)

- Decade 1: $1,650 (above)

- Decade 2: supplies $600 + one recoat $1,050 + occasional board swaps $300 ≈ $1,950

- Total 20‑year cost: $3,600

- Solid hardwood:

- Decade 1: $3,000

- Decade 2: supplies $600 + one refinish $2,400 = $3,000

- Total 20‑year cost: $6,000

Result: With a robust engineered wear layer, engineered remains less expensive to maintain over 20 years.

- Scenario B: Engineered with a thin wear layer (needs replacement ~year 15)

- Decade 1: $1,650

- Decade 2: supplies years 11–15 $300 + replacement $6,000 + supplies years 16–20 $300 = $6,600

- Total 20‑year cost: $8,250

- Solid hardwood: $6,000 (as above)

Result: If engineered must be replaced rather than refinished, solid wins by the second decade.

Takeaway: The engineered wear layer thickness (and your appetite for color changes that require sanding) is the pivot that decides long‑term cost.

Sustainability & Indoor Air Quality (IAQ)

- Refinish vs. replace: Extending a floor’s life through recoats or refinishing is usually greener than tearing out and replacing. That favors solid hardwood and engineered with thick wear layers.

- Materials: Engineered uses less slow‑growth hardwood in the core; solid is all hardwood but can last generations if maintained.

- Low‑VOC choices: Choose low‑VOC cleaners and finishes; microfiber dusting and mats reduce how much chemical you need at all.

The Practical Takeaway (Decision Flow)

- Want lowest daily effort and forgiving stability across seasons? → Engineered with factory UV.

- Planning to stay long term and want the ability to restain or reset the floor multiple times? → Solid hardwood (or engineered with ≥3–4 mm wear layer).

- Need quick spot repairs in a busy household? → Consider hardwax‑oil systems (accepting periodic maintenance oil).

- Working in basements/radiant heat? → Engineered rated for the application.

A Simple Maintenance Calendar & Supplies

Weekly

- Dry dust (microfiber) in traffic lanes.

- Shake out entry mats.

- Quick pet‑zone check (bowls, litter boxes).

Monthly

- Damp mop with wood‑safe cleaner.

- Inspect and replace felt pads on chairs and stools.

- Check for shininess loss in high‑traffic paths.

Seasonal

- Verify RH ~30–50% with a hygrometer; adjust humidifier/dehumidifier as needed.

- Inspect door thresholds for sand/salt; add or refresh mats.

- Look for developing dullness → consider scheduling a screen & recoat before damage penetrates.

Every 5–10+ years (traffic‑dependent)

- Recoat when cleaning no longer restores appearance.

- Refinish (solid or thick‑wear engineered) if you want a color change or have substantial wear.

Shopping list: Wood‑safe cleaner concentrate, two microfiber pads (one on deck, one in the wash), felt pads, hygrometer, touch‑up kit (filler + stain pen matched to your floor).

Myths to Retire

- “Engineered isn’t real wood.” The top layer is genuine hardwood; that’s what you see and touch.

- “You can steam clean wood.” Steam drives moisture into seams—skip it.

- “Engineered can’t be refinished.” It depends on wear layer thickness; some can be sanded once or twice.

- “Harder species don’t scratch.” Finish and grit control matter more day to day than raw Janka numbers.

FAQs

Can engineered wood be sanded and refinished?

If the wear layer is ~3–4 mm or thicker, usually yes (often once, sometimes twice with care). Thin veneer products typically cannot be sanded; rely on recoats and board swaps instead.

How often should I recoat?

There’s no fixed calendar. When regular cleaning can’t restore the look and micro‑scratches are visible across the light, it’s time. For many households, that’s every 7–12+ years for tough UV finishes and more frequently for oiled floors (with the benefit of easy spot maintenance).

What’s the best cleaner?

Use the manufacturer‑approved wood floor cleaner. Avoid vinegar, soap‑based products that leave films, and anything that says “restorer” unless you’re prepared to de‑gloss before recoating.

Do sunlight and UV matter?

Yes. Wood can amber or lighten depending on species and finish. Use window films, rugs, and rotating furniture to even out exposure; lighter, natural stains show less shift.

Which is best for basements?

Only engineered wood that’s rated for below grade (and installed with proper vapor control). Keep humidity managed to avoid musty conditions; wood still isn’t the right choice for damp basements.

What about pets?

Choose matte, textured finishes. Keep nails trimmed, use runners in “pet highways,” and place mats under bowls. Hardwax oil is forgiving for spot refreshes; factory UV finishes resist micro‑abrasion very well.

Glossary (Quick Definitions)

- Screen & Recoat (Buff & Coat): Light abrasion + new topcoat without sanding to bare wood.

- Wear Layer: The thickness of real hardwood above the core on engineered planks.

- Micro‑Bevel: Slightly eased edge on prefinished boards; can catch dust.

- Hardwax Oil: Penetrating oil finish that needs periodic maintenance but spot‑repairs well.

- Janka Hardness: A measure of wood’s dent resistance.

- Cupping/Gapping: Board edges rising due to moisture (cupping) or boards separating in dry air (gapping).

If you want lowest‑effort living with minimal seasonal drama, go engineered with a factory UV finish and keep a recoat on the long‑term calendar. If you want a floor you can reinvent over decades—new stain, fresh start—solid hardwood (or engineered with a thick wear layer) gives you that reset button.

Want this decision distilled for your home? Share your square footage, climate, finish preference, and household profile (kids/pets) and I’ll tailor the MWI scores and a 10‑ vs 20‑year cost plan to your exact situation.